The fasteners are manufactured by using the iron. These days, many kinds of fasteners are available in the market. Though the iron tends to corrode and corroded fasteners weaken easily and quickly. To save such scenarios, it is coated with some different chemically dependent materials to create them anti-corrosive. It can also be used in any application area with greater strength. When picking the various types of the fasteners, people should consider the high tensile fasteners as they are made with top-notch quality raw material and manufactured for the heavy load applications, especially.

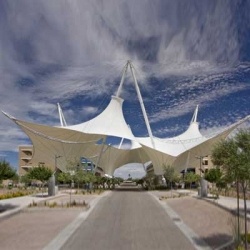

The coating of such fasteners tells the strength and working capability of the products. Many Tensile structure manufacturers install them in the big projects like high-rise building construction. They also deliver the following benefits which are available at the modest price range.

Aesthetics: The fasteners are appealing and grab attention at first sight instead of boring and dull ones. It is because the design matters the most. For a similar purpose, the coated fasteners can assemble the machine and sell them without making efforts. They provide an attractive and visible appeal.

Ease Of Use: Such fasteners serves good application use as well as offering great ease of usability. It is one of the most common reasons to plate the fasteners with some other materials. The materials allow the good companionship while they are used in the water.

Damage Protection: The iron is a strong material. It gets more strong when added material by coating it. As we know, positive and positive creates a big positive impact. It helps to avoid manufacturing as well as applicating damage of the products, also allows the users to utilize it in an efficient way.

Global Tensile Structure is one of the best Tensile structure suppliers and different from other market players in this industry due to many reasons.